X-Ray Photoelectron Spectroscopy (XPS)

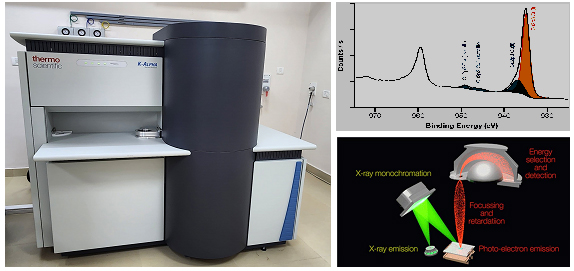

X-ray photoelectron spectroscopy (XPS) is a powerful analytical technique used to examine the surface of materials, providing valuable insights into both elemental and chemical composition. XPS is extremely surface sensitive — it measures approximately the top 10 nanometers of the surface of the sample. This surface specificity, combined with the ability to quantify the chemical composition of the surface, makes XPS extremely useful for materials analysis.

XPS can measure the elemental composition, empirical formula, chemical state, and electronic state of the elements within a material. XPS spectra are obtained by irradiating a solid surface with a beam of X-rays while simultaneously measuring the kinetic energy of electrons that are emitted from the top 1 to 10 nm of the material being analyzed. XPS is widely used as important characterization tool in metal and metal oxide analysis, catalysis, defect analysis, 2D materials, thin films and coatings, battery materials, photovoltaic materials, microelectronic, glass materials, polymers, medical devices, medical and biological samples, geological materials.

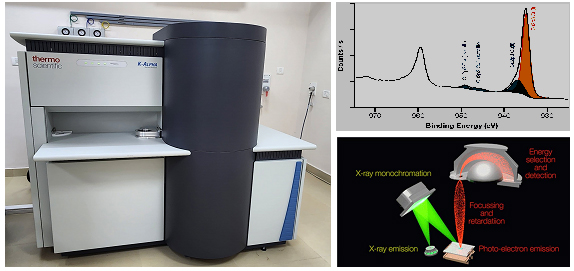

Thermo Scientific K-Alpha X-Ray Photoelectron Spectrometer (XPS) System

Specifications

Analyzer: 180° double-focusing hemispherical analyzer, 128-channel detector.

Energy Resolution: XPS: ≤ 0.50 eV, UPS: ≤ 0.12 eV.

X-ray Source: Al K-alpha micro-focused monochromator, Variable X-ray spot size (50–400 μm in 5 μm steps), X-ray power: 72 W.

Flood Gun Charge Compensation: Dual-beam charge compensation source, Ultra-low energy co-axial electron and Ar+ ion beam.

Ion Gun: Ion gun energy range: 200 eV - 4 keV.

UV Source: He (I) and He (II)

Vacuum system: Two turbo molecular pumps with automated titanium sublimation pump and backing pump

Additional Features: Tilt module for angle-resolved XPS, depth profiling, Sample bias module for work function measurements.

Specimen Size: Maximum size: 60 mm × 60 mm x 20 mm.

Requirements

- Analysis of only solid samples in the form of pallets, and thin films.

- Samples must be dry, clean, and should not degas or evaporate at very high vacuum condition.

- Samples containing S and I elements will not be acceptable.

- Samples must withstand temperature upto 300° C.

Procedure for Sample Submission

The instrument booking will be done via the Google form. The payment of charges as per the rate chart should be made in advance via SBCollect of SBI. A print copy of the Google Form along with fee payment receipt with the sign of the Head/Supervisor/Guide should be produced at the time of measurements.

Form for Submission of Requisition:

Click here for Requisition Form